Silica is a fundamental mineral for various industries due to its unique properties and versatility. In particular, the silica we offer is of superior quality, with a wide range of applications in sectors such as oil and gas purification, as well as acting as an isolator between them. If you’re looking for reliable silica, with characteristics ideal for your industrial process, you’ve come to the right place.

Technical Specifications of the Silica

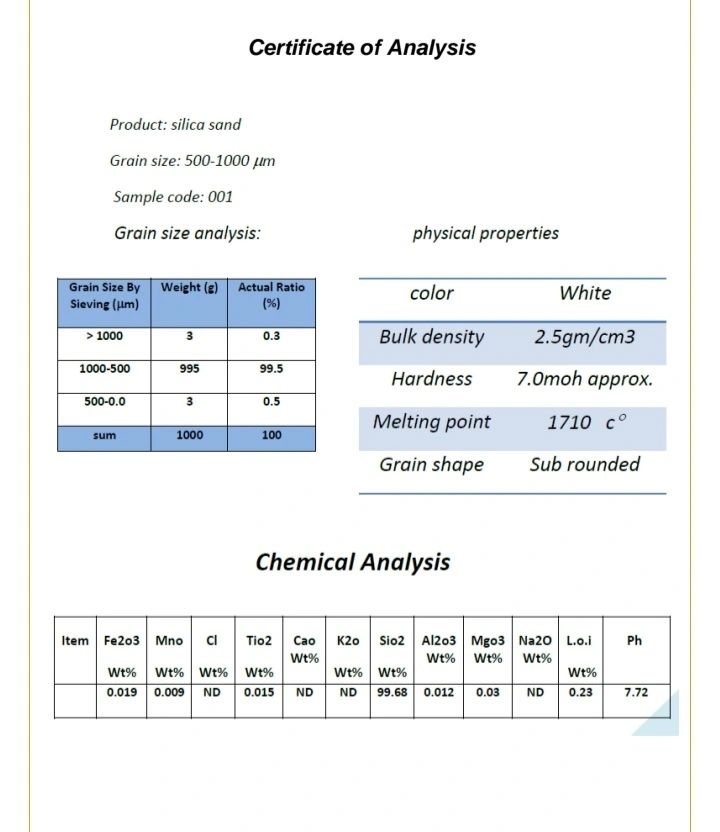

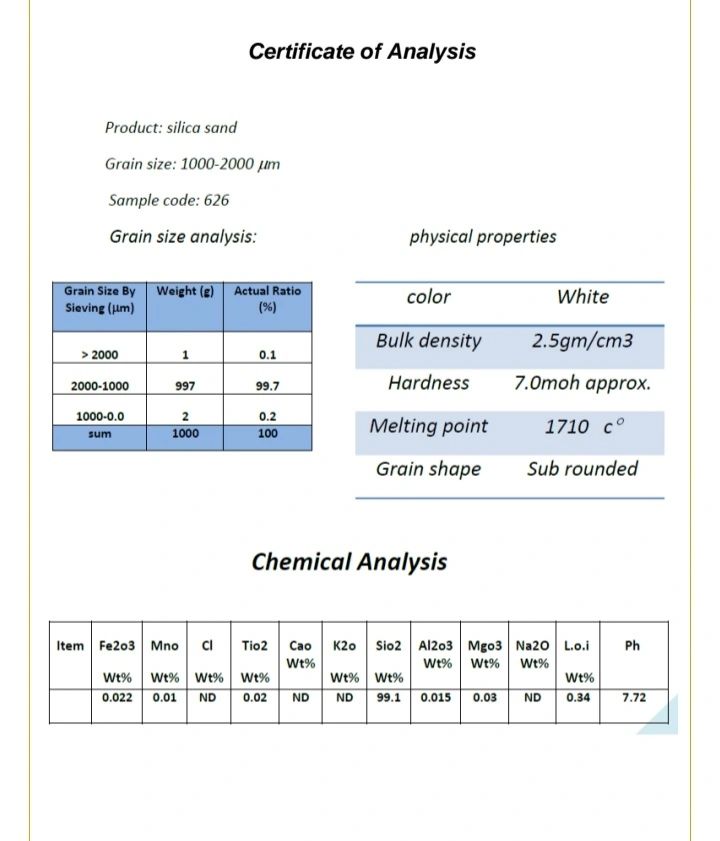

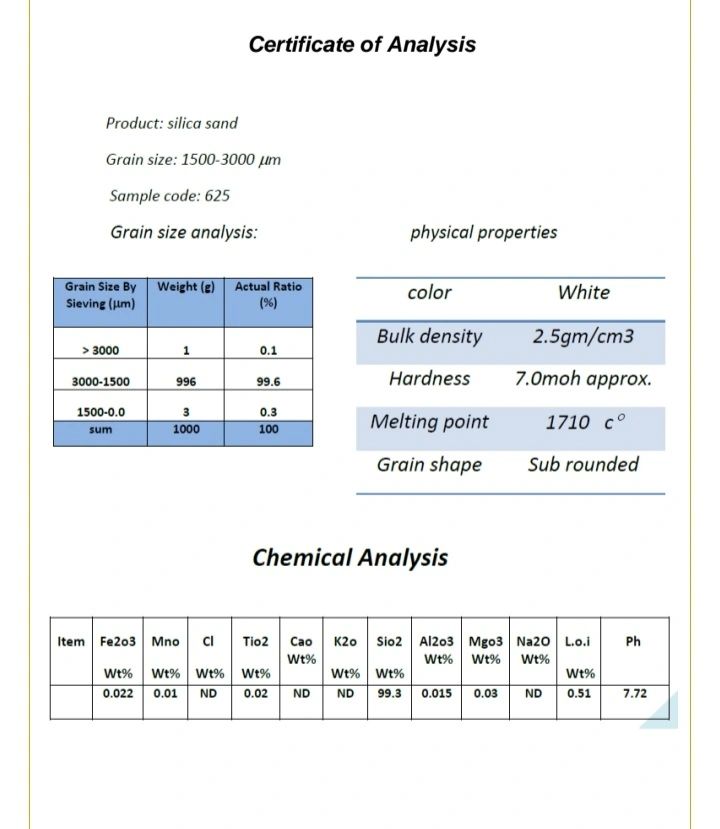

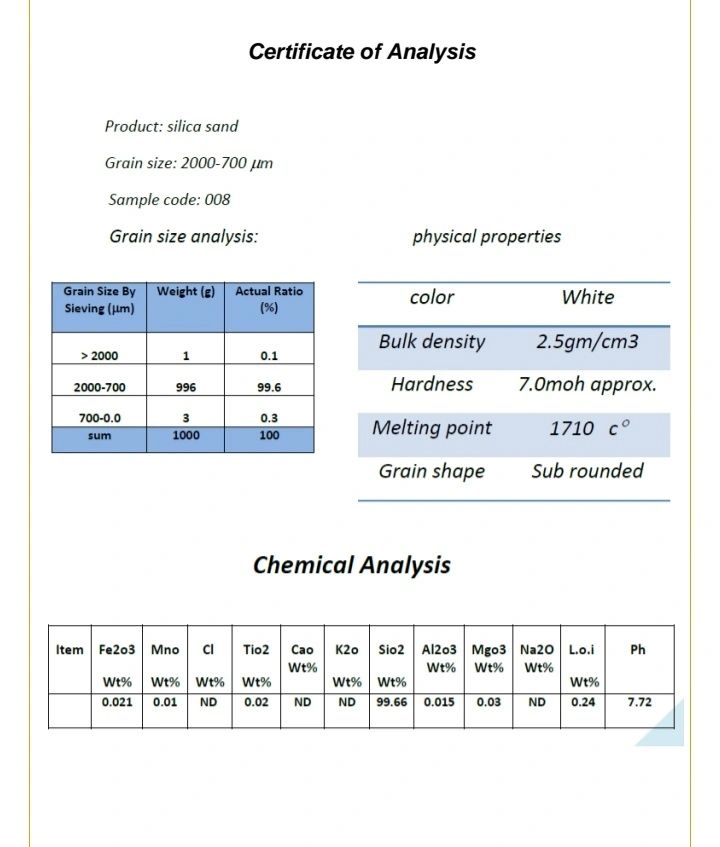

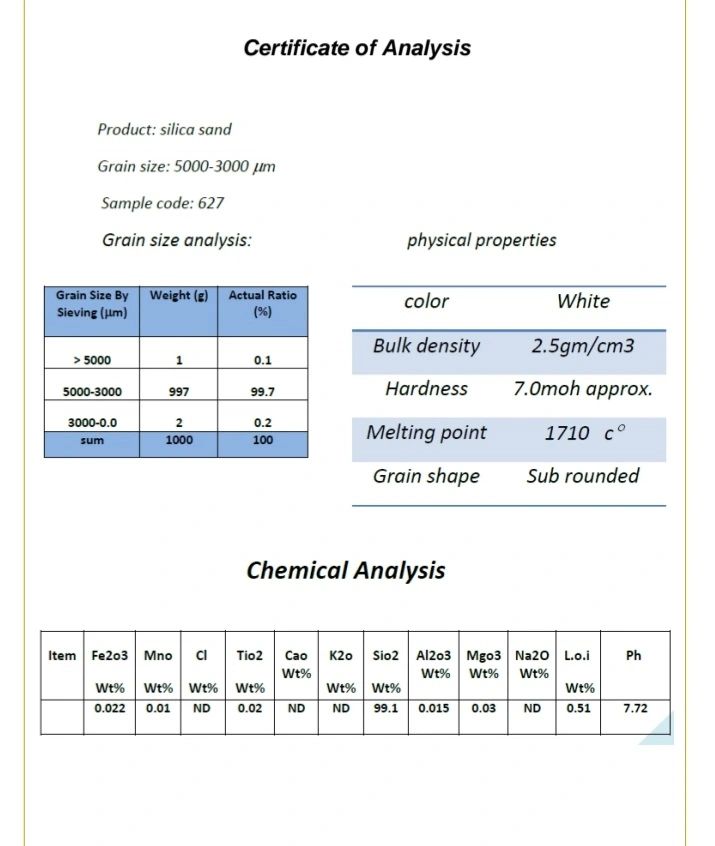

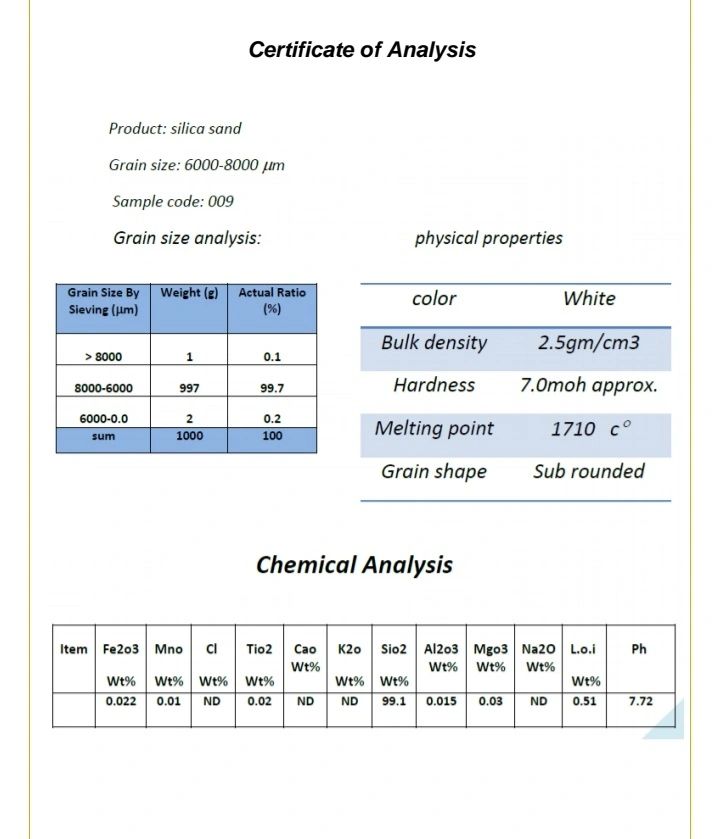

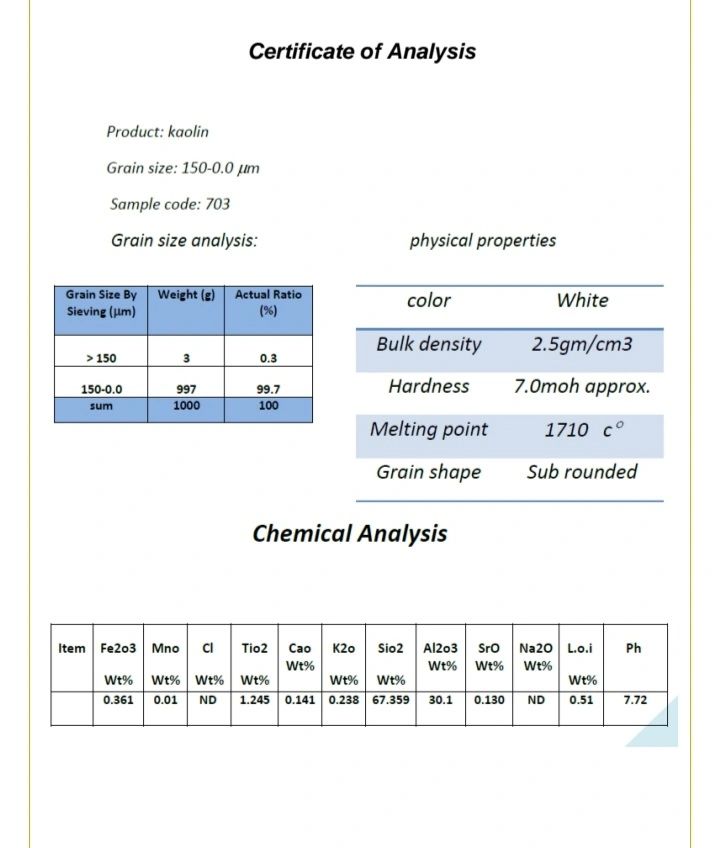

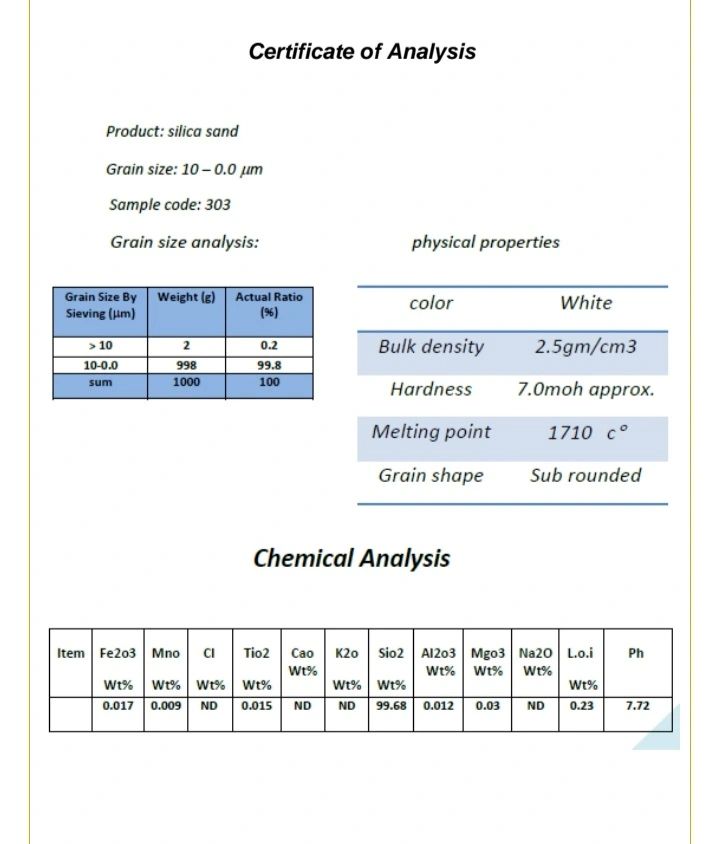

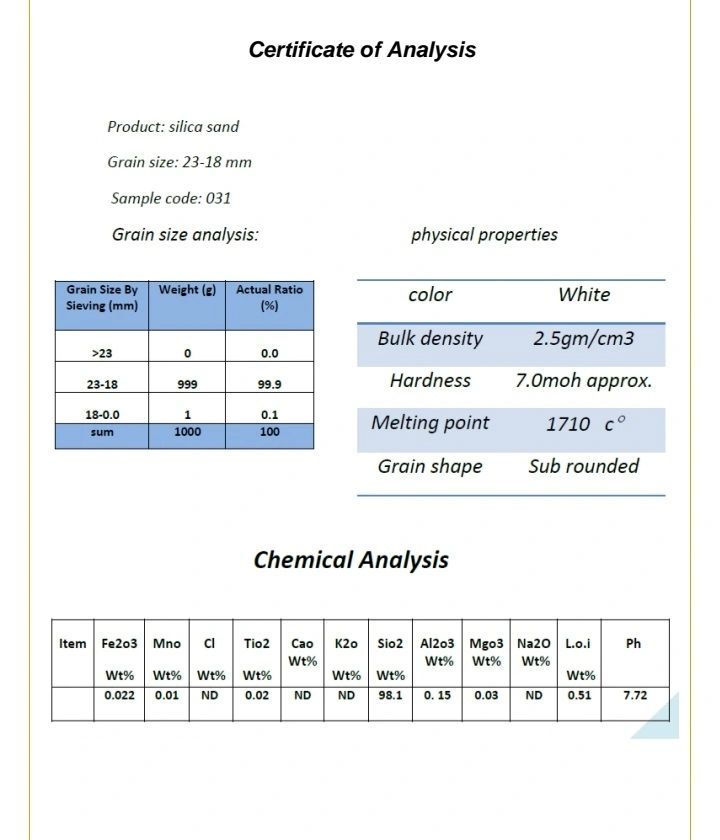

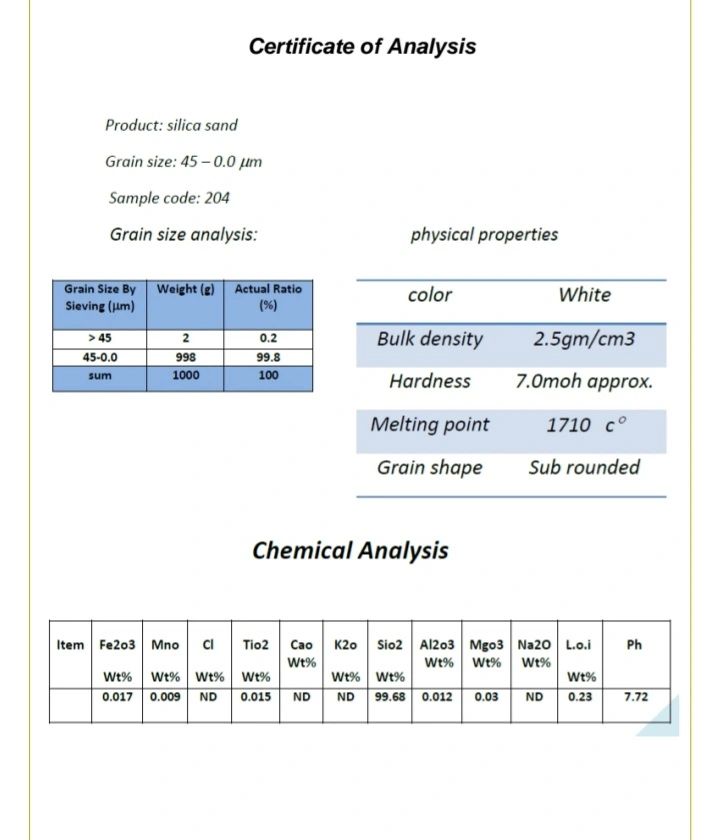

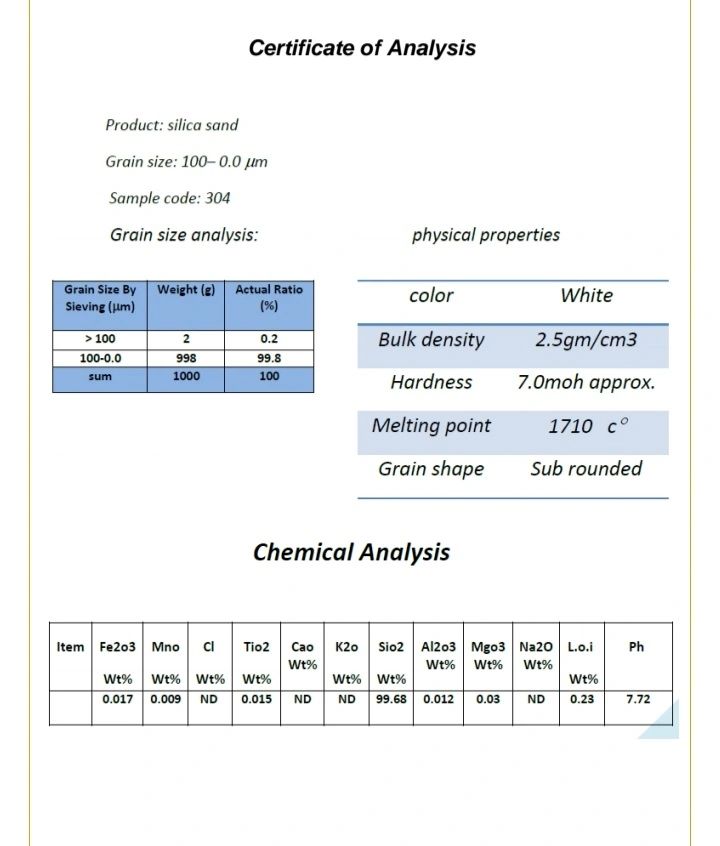

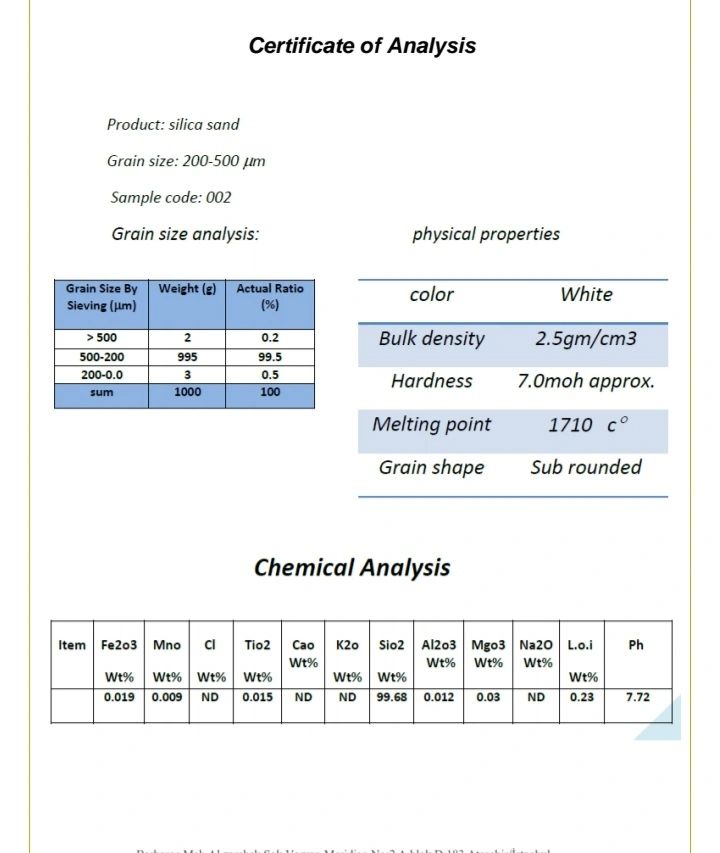

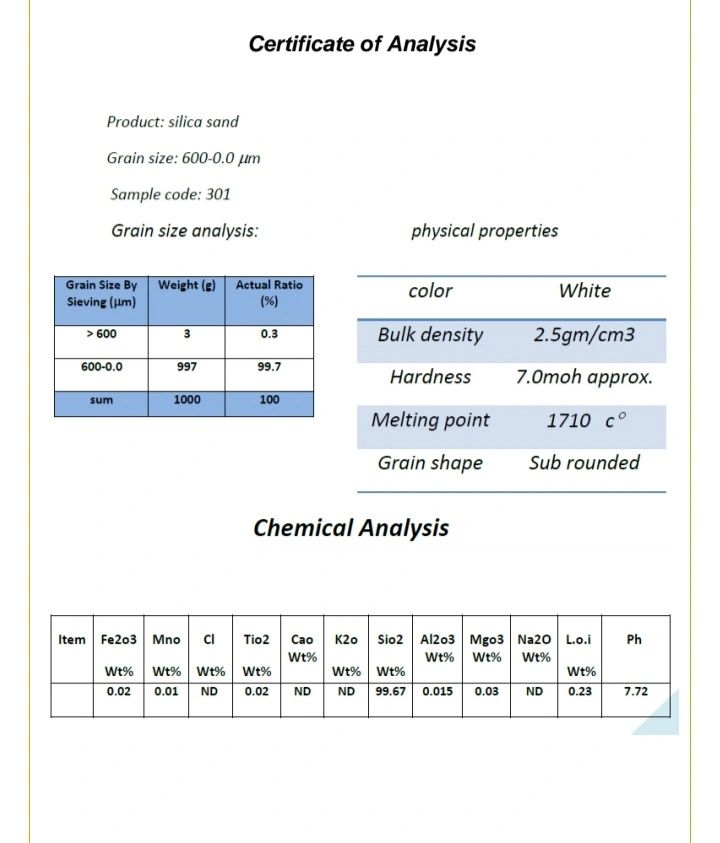

The silica we provide is analyzed and certified based on strict quality standards, including:

- Grain Size (μm): The available silica ranges in grain sizes such as 500-1000 μm, 1000-2000 μm, up to fine particles as small as 75-0 μm, suitable for different industrial processes.

- Physical Properties:

- Color: White, ensuring a consistent product appearance.

- Bulk Density: 2.5 gm/cm³, ideal for processes requiring good material compaction.

- Hardness: 7.0 Mohs approx., providing resistance in various applications, including high abrasion areas.

- Melting Point: 1710°C, giving the silica excellent heat resistance, making it ideal for high-temperature work environments.

- Grain Shape: Sub-rounded, which allows greater efficiency in filtration and purification processes.

Detailed Chemical Analysis

The silica we offer also undergoes a complete chemical analysis, making it reliable and safe for industrial use. Among the key components and their weight percentages, the following stand out:

- SiO2: 99.68% to 99.99%, depending on the type, being the main component responsible for silica quality.

- Fe2O3: Very low (0.017% to 0.022%), which is a desirable feature to avoid contamination in sensitive processes.

- Other Oxides: Such as Al2O3, MgO, and CaO, in controlled amounts, ensuring the silica is purified without unwanted impurities.

Industrial Uses and Special Applications

High-quality silica is an essential resource for various applications:

- Oil and Gas Purification: Special silica is widely used in the oil and gas purification process, as it aids in removing impurities. Its high porosity and filtration capacity allow for efficient separation of undesirable compounds, improving the final product’s quality.

- Isolation between Oil and Gas: In extraction and refining processes, silica acts as an excellent isolator between different elements, helping to prevent contamination and ensuring product purity.

- Chemical Industry: Silica is used in the manufacturing of glass, ceramics, concrete, and other chemical products due to its resistance and purity properties, which are essential for obtaining high-quality materials.

- Food and Pharmaceutical Industries: Beyond its industrial uses, silica is also used to improve the quality and safety of food and pharmaceutical products, ensuring the purity and effectiveness of manufacturing processes.

Why Choose Our Silica?

Our silica is not just a product; it’s a complete solution for the most demanding industrial needs. We work with a network of suppliers who guarantee product quality at every stage, from extraction to final delivery. This ensures that you receive the best silica, ready to optimize your processes and increase your productivity.

Get a quote https://wa.me/5562982920002

Conclusion

By choosing our silica, you’re ensuring the best product available on the market, with the confidence that you’ll be served by experts. No matter the industry you work in, we have the right product for your purification, isolation, and more. Get in touch with us and discover how our silica can transform your industrial processes.